With regard to light fittings, what is the difference between Fire Rated and TP(a)/TP(b)?

Here’s the quick answer:

“TP(a)/TP(b)” and “Fire Rated” are two terms that are both used in the UK building regulations in connection with fire safety and they mean completely different things.

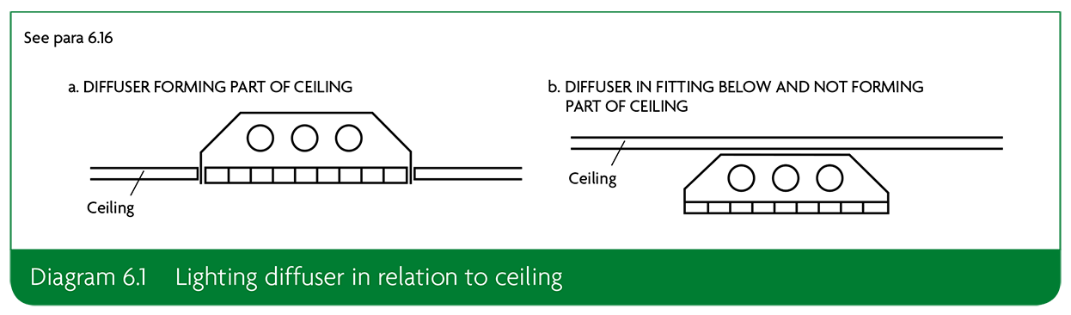

When a light fitting is recessed into a ceiling lining, such as with a recessed 600 x 600 LED panel, the lighting diffuser is deemed to be part of the ceiling. Therefore, the restrictions in the building regulations that apply to how ceilings are constructed for fire safety extend to any lighting diffusers that are part of the ceiling.

The purpose of restricting the type of thermoplastics that can be used is to limit the rate at which fire spreads across a ceiling.

The purpose of a fire resistant ceiling is to reduce the speed at which fire can travel vertically through a building and to extend the time, after a fire has started, during which the ceiling can still support a load. Ceilings are rated to BS476 as 30, 60, 90 or 120 minutes fire resistant.

Installing a recessed downlight involves making a hole in the ceiling and if the ceiling is classed as fire resistant this would compromise its fire resistant qualities. To overcome this, a fire rated downlight includes some intumescent material that, when subjected to extreme heat, expands to fill the hole made in the ceiling during installation.

Fire rated downlights are tested to BS476-21 for 30, 60 or 90 minutes so that they can be used in 30, 60 and 90 minute fire resistant ceilings without compromising the rating of the ceiling.

In summary, TP(a) and TP(b) relate to the flammability of the material from which a lighting diffuser, when it is part of a ceiling lining, may be made. Fire rated relates to the ability of a fitting to maintain the 30, 60 or 90 minute fire resistance of a structural ceiling in which it is installed.

|

Examples illustrating the difference between TP(a)/(b) and fire rated light fittings A 600 x 600 recessed LED panel must have a TP(a) or TP(b) rated diffuser because when installed it will be part of the ceiling. Ceilings have to be made of materials that limit the spread of fire. However, an LED panel does not need to be fire rated. This is because it is designed to be installed in suspended ceilings (which are classified as a lining) which are not required to have the load bearing, integrity or insulating properties of a fire resistant ceiling designed to BS476-21. Above a suspended ceiling in which an LED panel might be installed there is, typically, a concrete slab, and it is the concrete slab which has these necessary fire resistant qualities. A downlight needs to be fire rated if it is to be installed in a ceiling which is required to have load bearing, integrity and insulating qualities. Usually, these ceilings are made of timber and plasterboard. A fire rated downlight will typically have a front cover made of toughened glass, not thermoplastic, so the question of a TP(a)/(b) rating does not arise. Finally, if a downlight is to be installed in a suspended ceiling under a concrete slab it will not need to be fire rated because the suspended ceiling is merely a lining, not a structural element of the building with a fire resistance rating. |

Here’s the answer in more detail

TP(a) and TP(b)

TP(a) and TP(b) are terms used in the UK Building Regulations (Fire Safety, Approved Document B, Volume 2).

TP stands for thermoplastic, and that can include polycarbonate, acrylic (PMMA), polystyrene and polypropylene amongst other materials. Most thermoplastic materials are flammable to some extent.

Where the terms TP(a) and TP(b) are used in the UK building regulations the subject is “Internal fire spread (linings)”. The building regulations state that the materials used for linings (walls and ceilings that are not structural or load bearing) should “resist the spread of flame over their surface and have, if ignited, a rate of heat release or fire growth which is reasonable under the circumstances.”

This is relevant to the construction and specification of light fittings because if a lighting diffuser is recessed into a ceiling it is deemed by the building regulations to be part of that ceiling.

Diagram from UK Building Regulations (Fire Safety, Approved Document B, Volume 2 – Buildings other than dwellings).

If a lighting diffuser is part of a ceiling, and is made of thermoplastic, then it must be made of material that is either TP(a) or TP(b) rated.

What’s the difference between TP(a) and TP(b) rated materials?

The difference between TP(a) and TP(b) rated materials is in how they react under test conditions when a flame is applied to them. In summary:

For more details, please read article "What are TP(a) and TP(b) in relation to lighting?"

“Fire Rated” is not to be confused with TP(a)/(b)

“Fire Rated” describes a light fitting that is designed to be fitted into a fire resistant ceiling.

The UK Building Regulations, Approved Document B, volumes 1 and 2 concern fire safety and they define the fire resistant characteristics that are required of different building elements, including ceilings. In this context, a ceiling is a load bearing element, not a lining. Generally, load bearing ceilings are required to be fire resistant for 30, 60 or 90 minutes, depending on the type of building, the position of the ceiling within the building (eg in a basement or on higher floor) and the presence (or not) of other fire precautions such as sprinkler systems.

The fire resistance of a load bearing ceiling is determined by testing according to BS476-21. In brief, this test involves constructing a ceiling and then igniting a fire beneath it. Varying the construction of the ceiling (eg changing the spacing of the timber beams or the number of layers of plasterboard) changes the duration for which the ceiling will last under test.

To pass a test according to BS476-21 a ceiling must survive for the prescribed duration (30, 60 or 90 minutes) under test, according to 3 criteria:

1.Loadbearing. The resistance of the ceiling to collapse when the floor it supports is loaded to specific limits

2.Integrity. The resistance of the ceiling to fire penetration. For example, if a piece of plasterboard fell from the ceiling before the 30, 60 or 90 minutes duration had elapsed, this would constitute a fail, because integrity had been lost.

3.Insulation. The ability of the ceiling to resist the transfer of excessive heat to the floor it supports.

If, under test, a ceiling should fail to meet any of these criteria before the intended test duration (30, 60, 90 minutes) had elapsed, then the ceiling would have failed the test.

TP(a)/(b) and Fire Resistance in the UK Building regulations

TP(a)/(b) is concerned with limiting fire spread via linings, which are non-structural elements of the building.

Fire resistance and the fire rating of light fittings are concerned with limiting fire spread vertically in a building and in maintaining the load bearing ability of structural elements during a fire to prevent premature collapse.

How do light fittings impact the fire resistance of a ceiling?

Installing a downlight in a ceiling involves making a hole in the plasterboard – and this can have a significant impact on the loadbearing, integrity and insulating qualities of the ceiling. Therefore, any light fitting designed to be recessed into a fire resistant ceiling should be constructed to preserve the fire resistant qualities of the ceiling.

A fire rated downlight is one that has been designed and tested to maintain the fire resistant qualities of the ceiling in which it is installed.

How does a fire rated downlight work?

Most fire rated downlights rely on intumescent materials. When an intumescent material gets very hot it expands. A fire rated downlight will usually have a gasket made of intumescent material, and in the event of a fire this expands to seal the hole made in the ceiling plasterboard when the fitting was installed, so that flame cannot spread into the ceiling void.

Other fire rated downlight design concepts exist. Some rely on a metal can structure to cover the hole and others rely on a shutter mechanism that automatically closes when exposed to heat.

What are the different ratings that apply to fire-rated downlights?

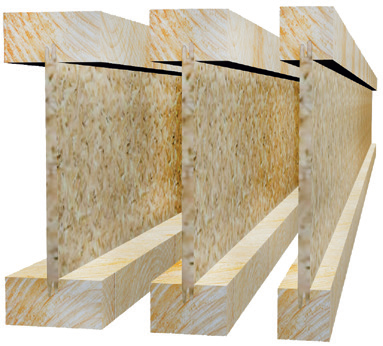

Fire rated downlights are rated not only according to duration (30, 60 or 90 minutes) but also according to the type of ceiling in which they may be installed (solid timber joist, I joist and steel web joists).

Solid timber joist ceiling

|

Conventional solid timber ceiling joists. To complete this construction, plasterboard will be fitted to the underside of the joists and chipboard or timber boards to the upper side. The size & spacing of the joists, and the number of layers of plasterboard will determine the fire resistance of this ceiling. |

|

I joists. These take the place of solid timber joists in the majority of fire resistant ceilings now being built in the UK. Depending on the brand and the application the overall depth, the thickness of the OSB web and the dimensions of the top and bottom chords will vary. |

|

Steel web joist. As with the I joist, the dimensions of the main elements will vary depending on the brand and application. |

These three types of ceiling joist all behave differently in a fire, so it is necessary that fire rated downlights are tested for each type of ceiling. For example, a fire rated downlight that is suitable for use in a 30 minute solid timber joist ceiling may not be suitable for use in a 30 minute I joist ceiling.