IN LIGHTING, WHAT DOES “FIRE RATED” MEAN?

A fire rated light fitting is one that is designed to preserve the 30, 60 or 90 minute fire resistant quality of the ceiling in which it is installed.

Background

Many ceilings are designed to be fire resistant and this is a requirement of the UK Building Regulations. The purpose of a fire resistant ceiling is to slow the spread of fire vertically within a building, and this is judged by testing against 3 criteria:

Anything, such as a light fitting or a service duct, that is installed by making a hole in a fire resistant ceiling could invalidate the ceiling’s fire resistance rating.

Fire rated light fittings are designed in such a way that they do not impair the fire resistant qualities of the ceiling in which they are installed.

Do all light fittings have to be fire rated?

No, they do not.

Light fittings only need to be fire rated if they will be recessed into a fire resistant ceiling.

What is a fire resistant ceiling?

A fire resistant ceiling is one of the structural (load bearing) elements of a building and is constructed to withstand fire for 30, 60, 90 or 120 minutes, as required by the UK Building Regulations, Approved Document B, section B3.

A fire resistant ceiling is not the same as a ceiling lining. A ceiling lining is non-structural and non-load bearing, covered in the UK Building Regulations, Approved Document B, section B2. Ceiling linings do not need to be fire resistant, but other measures to slow the spread of fire may apply to them.

Structural ceilings (B3) can achieve their fire resistant qualities in at least two different ways and this influences how light fittings can be installed.

How do different ceiling types influence the use of fire rated light fittings?

Some ceilings achieve their fire resistant qualities because they are made of non-combustible material such as concrete. However, it would be almost impossible to install a recessed light fitting into a concrete slab ceiling. Instead, if lighting is required under a concrete slab ceiling it could be surface mounted directly to the slab, suspended from the slab or recessed into a suspended (false) ceiling beneath the slab. In each of these cases the light fitting does not need to be fire rated.

Other structural ceilings may be made of combustible materials, such as timber and plasterboard, but constructed in such a way as to resist fire for 30, 60, 90 or 120 minutes. This type of fire resistant ceiling is commonly used in residential and smaller commercial projects. With these, fitting recessed lighting is very practical and popular, but the act of making a hole in the plasterboard to install a light fitting compromises the fire resistant quality of the ceiling, so fire rated fittings must be used.

How does a fire rated light fitting work?

Most fire rated light fittings work by having an intumescent gasket in their structure. When exposed to very high temperatures, as in a fire, the intumescent material expands and fills the hole that was made in the ceiling to install the light fitting. Closing the hole prevents flames from reaching inside the ceiling void which would hasten its collapse and increase the rate at which heat is conducted to the floor above.

|

A fire rated downlight, viewed from the rear. The circular red gasket is made of intumescent material and expands when exposed to extreme heat. This seals the hole in the ceiling, preserving its fire resistant rating. |

Other designs of fire rated downlight exist, but designs using intumescent material are the most common.

What does 30, 60, 90 mean in relation to fire rated downlights?

Fire rated downlights are classified according to the type of fire resistant ceiling in which they may be installed. A 30 minute fire rated downlight, for example, is one that has been subjected to, and passed, a 30 minute fire test in a ceiling designed to be fire resistant for 30 minutes.

If a ceiling is fire resistant for 30, 60 or 90 minutes any light fitting that is recessed into it must carry the matching fire rating. Only a 30 minute fire rated light fitting should be used in a 30 minute fire resistant ceiling and a 60 minute fire rated light fitting, for example, would not be an admissible alternative.

The 30, 60, 90 minute duration is not the only factor used to judge the suitability of a fire rated downlight in a particular ceiling. Attention also needs to be paid to the type of ceiling joist being used.

Solid timber joists, I joists and metal web joists

Fire resistant ceilings that may have light fittings recessed into them can be constructed using solid timber joists, I joists or metal web joists. All three types need to comply with UK building regulations with regard to fire resistance, but the precise way that each type performs in a fire is different.

Solid timber joist ceiling

|

Conventional solid timber ceiling joists. To complete this construction, plasterboard will be fitted to the underside of the joists and chipboard or timber boards to the upper side. The size & spacing of the joists, and the number of layers of plasterboard will determine the fire resistance of this ceiling. |

I joists

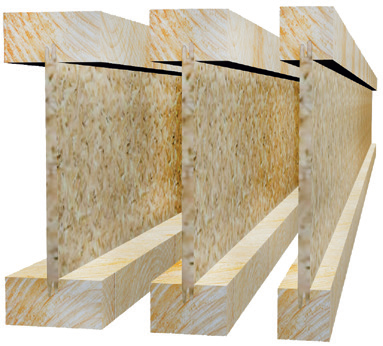

|

I joists. These take the place of solid timber joists in the majority of fire resistant ceilings now being built in the UK. Depending on the brand and the application the overall depth, the thickness of the OSB web and the dimensions of the top and bottom chords will vary. |

Steel web joist

|

Steel web joist. As with the I joist, the dimensions of the main elements will vary depending on the brand and application. |

These three types of ceiling joist all behave differently in a fire, so it is necessary that fire rated downlights are tested for each type of ceiling. For example, a fire rated downlight that is suitable for use in a 30 minute solid timber joist ceiling may not be suitable for use in a 30 minute I joist ceiling.

If you are looking for a suitable fire rated downlight for your project be sure to check not only the duration required, but check too that the rating is valid for the ceiling type involved.

120 minute fire rated downlights

Fire resistant ceilings are rated 30, 60, 90 or 120 minutes, but 120 minute fire rated downlights are relatively rare. This is for 2 reasons: