Self-test emergency lighting automatically performs tests on itself to ensure that it will function correctly in the event of a mains failure.

BS5266-1:2016 is the main standard for emergency lighting. It requires a short functional test of each emergency lighting fixture once a month and a full discharge test every year. Especially in larger buildings these tests can easily be overlooked, so BS5266 recommends the use of automatic test systems if the person responsible is not able to ensure that manual testing will be done.

There are three main types of automatic emergency lighting testing, self-test, wireless addressable test and DALI wired addressable test. Note that all of these are concerned with self-contained emergency light fittings (which each contain their own batteries), not emergency lighting that is connected to a central battery system.

Self-contained emergency light fittings all contain their own batteries and are connected to an unswitched live supply. In the event of a power failure the emergency fitting detects that the unswitched live supply is no longer at mains potential and the fitting is from that moment powered from its batteries.

A self-test emergency fitting therefore must check that:

In addition to these checks, BS5266 recommend that steps are taken during testing to ensure that not all fittings are tested at the same time as that would, temporarily, compromise the integrity of the emergency lighting provision. Therefore, a well-designed self-test emergency light fitting will be designed to operate as follows:

Step 1: Product is installed and is connected to mains power

Step 2: Under its own control the fitting charges its batteries for 24 hours

Step 3: The fitting carries out its own discharge test for 3 hours and then re-charges

Step 4: Anytime from 15-30 days later (the interval is randomly determined) the fitting undertake it own 30 second functional test

Step 5: 30 days later the 30 second functional test is repeated and repeated again after another 30 days till it has been done 11 times.

Step 6: On the 12th time the fitting conducts another full discharge test

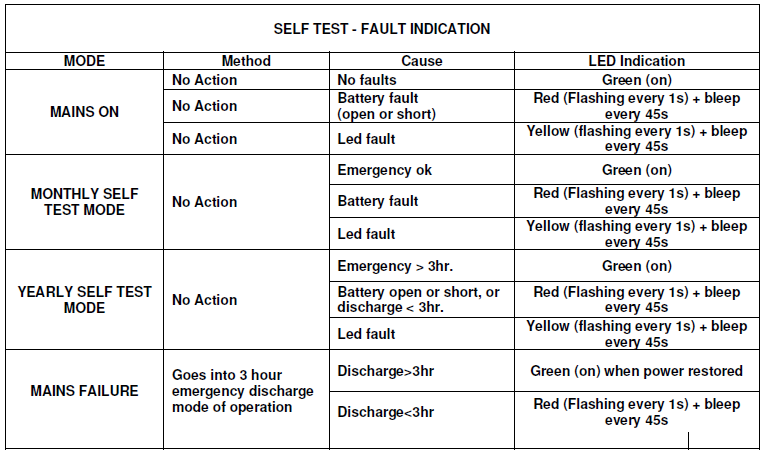

On completion of a monthly or an annual test, indicator LEDs and an audible buzzer will signal the status of the fitting. The status signals from NVC Lighting’s self-test products are as follows, and other manufacturers’ status signals are similar.

Every self-test emergency module or fitting contains some electronics and software.

Software in the fitting includes a timing (but not a calendar) function so that tests are scheduled at the correct intervals.

Electronic sensing circuitry monitors the current flowing into the LEDs. If the current drops below a threshold level it is an indication that the LEDs are not functioning and this will cause the yellow indicator LED to flash. Similarly, sensing circuitry monitors the battery terminal voltage and current and causes the red indicator LED to flash it the values sensed are out of tolerance.

There are three main benefits of having self-test emergency lighting:

Regular testing of emergency lighting is essential to avoid the risk of being in breach of the Regulatory Reform (Fire Safety) Order (2005). Breaching this statutory instrument brings the risk of fines and imprisonment. For details of the legal status of emergency lighting and emergency lighting testing, please read here

Manual testing is legal, but easily overlooked or carried out incorrectly. Therefore, the benefits of self-test emergency light fittings are:

We have self-test versions of all our emergency lighting products. This includes a self-test version of our popular plug-in emergency conversion kit. This enables any of our LED panels and LED downlights to be converted to emergency or self-test emergency. No special skill is required – they just plug in – so if you an installer it would be wise to keep a few of these kits to hand. You can use them on any project where our panels and downlight are being used.

Self-test is a great approach to emergency lighting testing in many situations, but it is not always ideal. It has two main drawbacks:

The alternative automatic testing method is addressable test. For more details, please check article "Addressable self-test emergency lighting"