Emergency Lighting Testing. How Often?

BS 5266 requires a short functional test every month and an annual 3-hour test. We offer 4 ways to test emergency lighting:

Manual testing

A key-switch is used to disconnect the permanent live supply from the emergency fitting. When disconnected the fitting switches to battery operation. It is necessary to observe the fitting to check it is working correctly and for the required duration.

Manual testing is ideal for small installations, but the burden of record keeping and remembering to do the test every month will be impractical for larger buildings.

All the fittings shown below are available in manual test versions.

Self-test

A self-test emergency fitting carries out its own test without human intervention or the need for a key-switch and the associated wiring. A self-testing emergency fitting is autono¬mous; it operates on its own without any communication with neighbouring fittings or a central control point. A tri-colour LED will indicate if the fitting is working cor¬rectly (green) or if it has an LED fault (yellow) or a battery fault (red).

Self-test has great advantages:

The self-test versions of our dedicated emergency lighting products are as follows:

|

Order Code |

Description |

|

Lexington LiFe Exit Box Maintained Euro Down Legend Self Test |

|

The self-test versions of our emergency conversion kits for high-bays, panels and downlights are as follows:

|

Order Code |

Description |

|

N/HB/STNM3L/PACK |

LiFe High Bay Self Test NM3 Emergency Pack |

|

LiFe Self Test M3 Emergency Pack for Recessed Product Ranges |

Wireless Addressable Test

These systems (for example, Casambi and Inventronics’ HubSense) use wireless mesh networking technology to enable emergency fittings to communicate with an app (on a smart-phone or tablet). In accordance with a testing schedule that the installer sets-up via the app, each fitting tests itself and then communicates the results to the app where the responsible person can see the test results and the status of each emergency fitting.

Wireless addressable test has many advantages. First, it saves the labour of manual testing. Secondly, it eliminates the risk that routine testing is overlooked. Third, it carries out tests according to a pre-arranged schedule, so that testing can always take place at a convenient time (not in the middle of a class, in the middle of a doctor’s consultation or while a film is showing in a cinema). Fourth, it automates record keeping. Fifth, it does not require additional wiring, so it is typically quick and easy to install.

For further information on wireless addressable systems, please check NVC Catalogue. Additional information is also available from our technical support team on +44 (0)121 457 6340.

Wired DALI Addressable Test

For larger sites we recommend a wired DALI addressable test system in which all the emergency luminaires are connected to a central controller on a DALI communications bus with each fitting having a unique address.

Periodically, the central controller will command each emergency luminaire to start a test sequence and report the results back to the central controller.

For more information on wired DALI systems, please check NVC Catalogue. Additional information is also available from our technical support team on +44 (0)121 457 6340.

This chart summarises the relative strengths if the 4 available methods for testing emergency lighting:

EURO LEGENDS

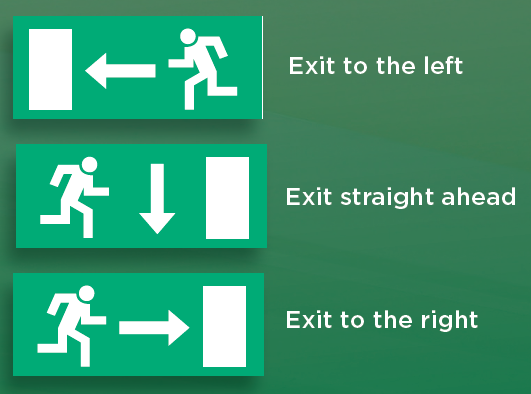

The European Signs Directive calls for the following legends, which are sometimes called “Euro legends”. They are easily distinguished by their use of an image of a man running towards a door. This is the style of legend supplied as standard with all our LED exit sign fittings.

These are the three Euro legends in common use.

Please note that The European Signs Directive is not explicit concerning the use of either an up or down-arrow to indicate “straight ahead”. Both are acceptable, but we supply the arrow-down legend as standard.

ISO7010 & BS5266

These 2 standards both use a single set of legends, sometimes referred to as “ISO7010” legends. They are easily distinguished by their use of an image of a man running through a door. These legends are available as optional extras with all our LED exit signs fittings.

There are the three ISO7010 legends in common use:

Note that ISO7010 and BS5266 are explicit that “straight ahead” is to be indicated with an up-arrow.