There are several faults commonly found in LEDs. Two of the most common are:

To understand these you need to know a little about how an LED works and how it is structured internally.

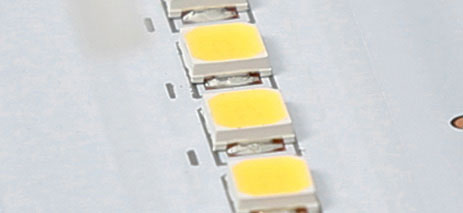

White light LEDs, as are used throughout the lighting industry, produce blue light. This is then changed to white light as it passes through a layer of phosphor chemicals. If you look closely at an LED the phosphor layer is usually visible as a yellow dot in the centre of each LED.

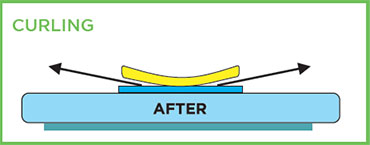

Curling and lamination can occur if the phosphor layer becomes partially detached from the substrate on which it should be fixed.

In a correctly assembled LED, all the blue light passes through the phosphor layer and is transformed to a consistent quality of white.

CURLING occurs when the phosphor layer starts to peel at the edges, allowing some of the blue light to escape without being transformed to white.

LAMINATION occurs when cavities appear under the phosphor layer. These have the effect of increasing the distance the light travels through the phosphor layer, so the light becomes more yellow than originally intended.

To check for curling or lamination, remove the diffuser (if there is one) from the LED light fitting in question and direct the beam of light directly at a mat-white painted surface. Especially on fittings with only a few LEDs, or where the LEDs are in a single strip, curling and lamination will be apparent in the form of irregularities in the colour of the light beam where it strikes the surface.

If curling is present, then more blue light will be escaping past the phosphors and a blue halo will be visible.

If lamination is occurring it is most likely that the centre of the light beam will be more yellow than the surrounding area.